What is Hollow Kick Molding Vapor Retarder System ?

Latest in Basement Waterproofing Drainage Engineering

This state-of-the-art drainage system removes water at an elevation below the floor and foundation, so the basement does not become submersed in water and hydrostatic pressure is reduced. It is truly the latest in basement waterproofing methods.

Why use Hollow Kick Molding?

What is the Vapor Retarder System?

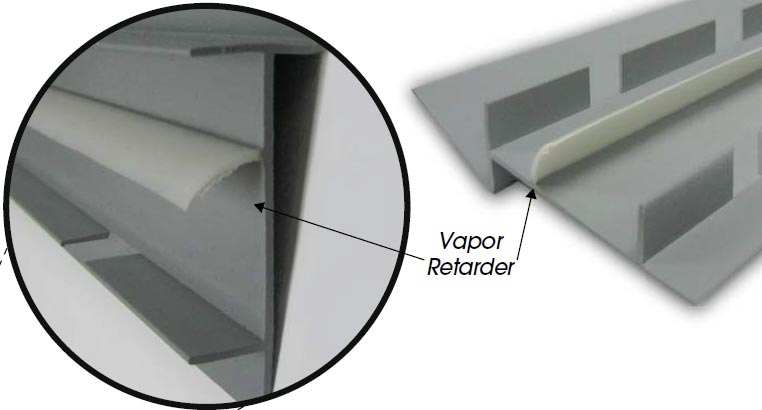

Hollow Kick Molding with built in vapor retarder is a linear through floor drainage molding installed at the Cove Area where the basement floor slab abuts the interior side of the foundation wall, creating a floating slab.

It directs water through the floor and into the drain tile pipe eliminating the possibility of water accumulating on the floor. It conceals and protects the drainage opening with an attractive cove plate molding and is the most effiective, affordable method to eliminate wet basements.

Following in Boccia’s tradition of innovation they are introducing the next generation of Hollow Kick Molding with a built in vapor retarder to reduce the pollutants that may permeate the floor cove. This new design will still provide the same drainage characteristics that the industry has come to rely on with the protection of a sealed floor.

Recommended Installation